Iityhubhu zokuzalisa umatshini weplasticlaminate kunye ne-aluminium ityhubhu (ukuya kuthi ga kwi-320 ppm)

IINKCUKACHA ZEMVELISO

Inkcazo emfutshane yomatshini wokutywina weplastiki

1. Iumatshini wokutywina weplastiki ityhubhuisebenzisa i-Siemens 10-intshi yokuchukumisa isikrini kunye ne-Japan Keyence PLC-KV8000 software yokulawula.

2. ityhubhu yenkqubo yokulawula i-filler yokusebenza kwe-servo kunye nengqiqo yokulawula ukunyakaza

3. Umsebenzi wokulawula: Emva kokuba ityhubhu isusiwe okanye imveliso, kusekho ityhubhu ehlala kwikhonkco lombhobho - ukuvala

4. Umsebenzi wokhuseleko (ukumisa okungxamisekileyo kunye nokutshintsha okukhuselekileyo) zonke iingcango zivaliwe xa ityhubhu yokugcwalisa isebenza.

5. umatshini wokuzalisa umbhobho ozenzekelayoinazo Zonke izixhobo ze-alam ezichaziweyo zinokuhlengahlengiswa ngephaneli yolawulo

6. I-servo yombane ye-tube ye-filler inokulungelelanisa isantya ngabanye, kwaye isantya sokuvelisa umatshini wonke sinokulungiswa.

7. Isixhobo sokungena sisebenza ngesantya esiphantsi

8. Iphaneli ephambili yokulungelelanisa zonke izicwangciso zemveliso

9. Iphaneli yokusebenza ibonisa ubuninzi bemveliso kunye nesimo somgca wemveliso

10. Ngokweemfuno zabathengi, setha iiseti ezininzi zeefomula zetyhubhu yokuzalisa

11. Iumatshini wokuzalisa umbhobho ozenzekelayoindawo yolawulo inokuseta imisebenzi yeparameter

12. Umatshini wokuzalisa ityhubhu ngokuzenzekelayo unepaneli yokusebenza ekhuselwe ngamanqanaba e-3 ahlukeneyo okusebenza.

13. Ikhabhinethi yombane ezimeleyo yensimbi engenasici ene-air conditioning, inqanaba lokukhusela lifikelela kwi-IP65 okanye ngaphezulu.Iifowuni zekhebula phakathi kweekhabhinethi zombane kunye noomatshini zisebenzisa i-cable trays evaliweyo, kunye neentambo zingena ukusuka phezulu kumatshini kwinqanaba eliphezulu.

Kwixesha elizayo, inkqubo yokulawula inokusebenzisa i-Siemens profitnet ukudlulisa idatha kwi-MES kwaye idibanise nenkqubo ye-MES.

Iibhubhu zokuzalisa umatshini weplastiki yeplastiki kunye ne-aluminium ityhubhu

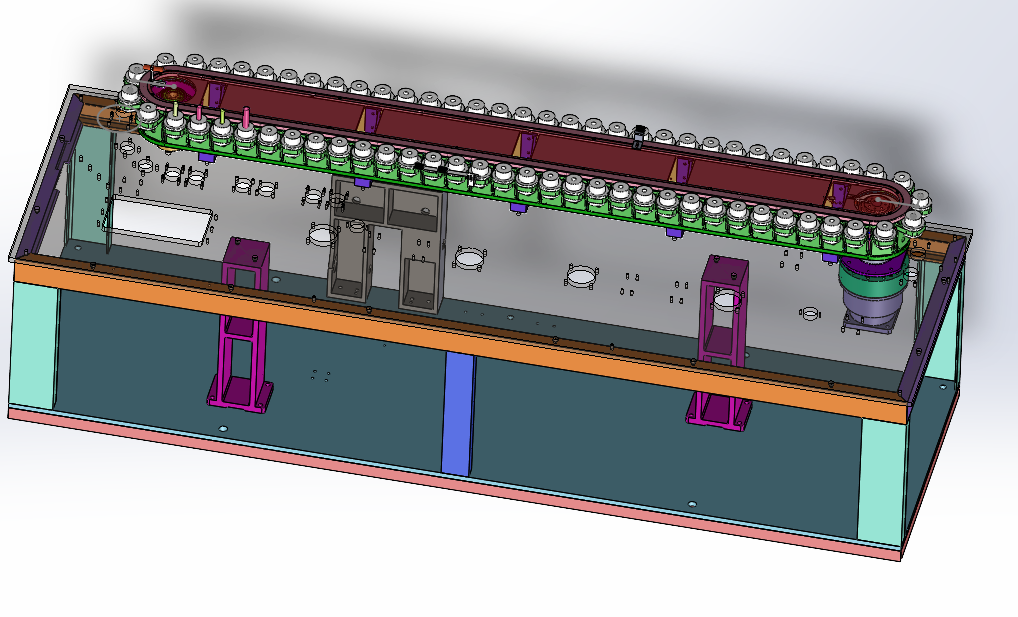

LFC4002Umatshini wokugcwalisa iityhubhusisitishi sesine sokuzalisa kunye nokutywina i-full-servo plastic tube yokutywina umatshini wokutywina ngokuzimeleyo, oyilwe kwaye wenziwe yinkampani yethu.Kufanelekile ukuzalisa iinkcukacha ezahlukeneyo zeetyhubhu ze-aluminium-iplastiki edibeneyo eyinyumba okanye engekho inzala, iibhubhu zeplastiki kunye neebhubhu ze-aluminium.Isantya sokuyila ngamatyhubhu angama-360 / umzuzu, kwaye eyona santya siphezulu sokuvelisa esiqhelekileyo sombhobho wokuzalisa ngamashubhu angama-250-340 / umzuzu.Ukuchaneka kokuzaliswa ngu-≤±0.5%.Umbhobho we-aluminium uvalwe ngokutywinwa ngokutywinwa, umbhobho we-aluminium-iplastiki ehlanganisiweyo ivalwe ngomoya oshushu okanye ukufudumala kwe-high-frequency, kwaye umbhobho weplastiki uvalwe ngokutywinwa kwangaphakathi ukufudumeza komoya oshushu.

Umatshini wokuZalisa iityhubhu Indlela engundoqo yothumelo:

Umatshini wokuzalisa umbhobho ozenzekelayoithatha isikhokeli sentsimbi esidityanisiweyo sentsimbi, isibambi sekomityi ene-anti-vibration, kunye neseti yesibambi sekomityi ye-4kW ye-servo eqhutywa ngamaxesha athile.Umatshini wokutywina weplastiki ityhubhu umisela isantya esiphezulu kunye nokuzinza kwezixhobo zokupakisha.

Iityhubhu zokuzalisa umatshini wetyhubhu yekomityi yokuhambisa isixhobo iqulathe iintsimbi ezintathu ezigrunjiweyo eziphezulu, ezisezantsi kunye necala.Iibheringi ezintathu ezijikelezayo zifakwe kwisihlalo sekomityi yetyhubhu, kwaye iibheringi ezijikelezayo zihamba ngokuthe ngqo kwi-grooves kwaye ziqhube i-hose.Itsheyini yekomityi yetyhubhu ayinxibi.Kukwakho neebheringi ezimbini zenaliti ezingaphezulu nezisezantsi ezifakwe kwizikhonkwane zokujikeleza.

umatshini wokutywina weplasitiki wetyhubhu Umbhobho we-hose conveyor hinges kwaye ulungise izihlalo zetyhubhu (indawo enemibhobho emithathu, umzila wentsimbi yesikhokelo) omnye komnye ngebhanti lokuhambisa elinamazinyo.Ibhanti lokuhambisa elinamazinyo libaleka ngokungqongqo ngokwendlela yokuhanjiswa kwevili lokuqhuba.Ikomityi yetyhubhu ixhonywe kwiringi nganye yesitulo setyhubhu.I-tube cup cup yenziwe ngezinto zePOM kwaye ihlangabezana neenkcukacha ze-hose kunye neemfuno zoyilo.

Iityhubhu zokuzalisa umatshini wokukhuselwa kwekhonkco lokuhambisa umthwalo wenziwa ngokubuyisela imvelaphi echanekileyo yokulinganisa i-torque limiter efakwe kwivili lokuhambisa, elinobomi obude benkonzo.Ukuba ikhonkco lombhobho libambekile, i-clutch inqanyuliwe, iswitshi yokusondela iyavuselelwa, kwaye umatshini uyayeka kwangoko.

Iityhubhu zokuzalisa umatshini Inkqubo yokucoca kwi-Intanethi

1. Umatshini wokutywina weplastiki ityhubhuinkqubo yokuzalisa kunye ne-hopper inokucocwa ngokuzenzekelayo yisikhululo se-CIP kwi-loop evaliweyo ngexesha elifanayo.

2. Ngaphambi kokuqala i-CIP, i-nozzle yokuzalisa ifakwe kunye ne-CIP ye-dummy cup ethile, kwaye i-liquid yokucoca iya kukhutshwa kumatshini wokuzalisa ngombhobho oqhagamshelwe kwi-CIP dummy cup.

3. Indawo yokusebenzela yeCIP (ebonelelwe ngumthengi) ibonelela ngearhente yokucoca ekungeneni kwehopper.Ibhola yokutshiza ifakwe kwi-cylinder, kwaye ibhola yokutshiza itshiza i-agent yokucoca kwindawo yangaphakathi ye-cylinder.Inkqubo yokuzalisa umatshini wokutywina iityhubhu yeplastiki yenzelwe ngokwemigaqo yococeko, kwaye i-CIP yokucoca i-fluid inokufikelela kuyo yonke indawo, imibhobho kunye nezixhobo ezidibana nemveliso ngexesha lenkqubo yokuvelisa.Iinxalenye ezihambayo ezidibana nemveliso ngexesha lenkqubo yokuvelisa, njengeempompo zepiston, i-agitators, njl., Ziya kuphinda zijikeleze ngokufanelekileyo ngexesha lokucoca i-CIP ukuqinisekisa ukuba zonke iindawo ezihambayo ziyakwazi ukucocwa ngokupheleleyo.

4. Umbhobho wokudibanisa ukucoca ulwelo lokubuyela kwisistim ye-CIP yomthengi (ipompo yokubuyisela ayifakwanga kwi-scope of supply)

5. Ukuseka imijikelezo yokucoca kunye ne-disinfection ngokweemfuno zabathengi, kwaye konke ukucocwa kunye nokutshatyalaliswa kweentsholongwane kulungiselelwe kwisikhululo se-CIP.

6. Iiparamitha ezifana neqondo lokushisa, uxinzelelo, izinga lokuhamba kunye nexesha lomjikelezo weCIP lunokusetwa yisikhululo seCIP ngokweemfuno zabathengi.

7. I-nozzle yokuzalisa umatshini wokutywina we-tube yeplastiki nayo ingakhutshwa ngokukhawuleza kwinkqubo yempompo yokucoca ngaphandle kwe-intanethi.

8.CIP traffic ifuna 2T/H okanye ngaphezulu

Umatshini wokuZalisa iityhubhu owamkela iirobhothi ukondla iityhubhu (iityhubhu eziyi-15x2 ezithathwe kwimiqolo emibini ngexesha ngalinye, amaxesha ali-9-12/ngomzuzu):

Ngokutsho kwenkqubo ecwangcisiweyo, le robhothi ikhupha imiqolo emibini yemibhobho sihlandlo ngasinye, iwadlulisele kumphezulu wekomityi, ize iwafake nkqo kwityhubhu.Irobhothi isebenzisa indlela yokuxhasa ityhubhu, kwaye isebenzisa insimbi engenasici ukuqinisa iminwe.Yenziwe, inokukhutshwa ukuze kucocwe kwaye kubulawe iintsholongwane okanye kubulawe iintsholongwane ngesitshizi sehydrogen peroxide.

I-grating ibona ukuba kukho i-tubeleft emnweni we-robot engazange ifakwe kwi-tube cup cup, kwaye isebenze indlela yokukhupha ukususa i-hose emnweni, kwaye emva koko ithathe ityhubhu.

I-LFC4002 Umatshini wokuzalisa iiTubhu unezi nzuzo zilandelayo:

a.Inkqubo yokulawula: I-tube yokuzalisa ithatha i-Siemens touch screen kunye neJapan Keyence isilawuli sokunyakaza, i-servo ibhasi eqhutywe ngokupheleleyo;ingxolo ingaphantsi kwe-75 decibels.

b.Indlela ye-Indexing: ityhubhu ye-filler isebenzisa inkqubo ye-servo njenge-indexer, kwaye iphuhlisa i-software ehlukeneyo yokwandisa i-dynamic to static ratio, yandise ixesha le-static lokuzaliswa kunye nokutywinwa, kunye nokuqinisekisa ukuba isantya esizinzile sesixhobo singaphezulu kwe-260pcs / min.

c.Cup chain guide guide: Umatshini wokuzalisa ityhubhu ozenzekelayo wamkela ukusebenza kwesikhululo ezine, i-alloy steel integral guide kaloliwe, kunye ne-anti-vibration ye-tube-bearing three-bearing cup holder locking mechanism.

d.Ukwahlulwa kweendawo: i-hose self-coca, ukulayishwa kwe-robot tube, i-servo flap tube ukulayishwa, ukulayishwa kwe-tube ngokuzenzekelayo, ukuzaliswa kunye nokutywinwa, ukukhutshwa kwe-servo tube kunye nezinye iindawo ziyahlukana ngokweemfuno ze-GMP.

e.Ukubekwa kwebhokisi yombhobho: Umatshini wokuzalisa ityhubhu ozenzekelayo uthatha uthutho oluphindwe kabini.Ibhokisi yombhobho ithuthwa kwinqanaba eliphezulu, libekwe kwiplatifomu ethathiweyo, kwaye ibhokisi elingenanto libuyiselwa kwinqanaba elingaphantsi.

f.Indlela yokulayisha ibhubhu: Irobhothi okanye umatshini wokulayisha umbhobho ungena kwiibhubhu, kwaye unokugcina iibhubhu ezingama-3000-4000.

h.I-Servo benchmarking: umbala ogulayo uphawu lokubanjwa kombala, indawo enkulu yokujikeleza kwe-torque servo, isantya esiphezulu kunye nokuzinza.

i.Ukuzaliswa kwe-Servo: Umatshini wokuzalisa ityhubhu ozenzekelayo uthatha i-servo drive epheleleyo kunye nokuzaliswa kwempompo ye-ceramic epheleleyo, engasokuze iguge.

j.Umbhobho we-aluminiyam obambayo kunye nowenza umcaba: Indlela yokucinezela kunye nokucweba kwesixhobo sokutywina umsila ekuqaleni yayisisikere sohlobo lwesikere esisiba caba, esinokucinezela umoya lula kwityhubhu.Ngoku itshintshelwe kwi-horizontal clamping kunye ne-flatten mechanism, engenalo uthuli kwaye inqanda ukuqhuba igesi kwityhubhu.

k.Ukutywinwa komsila wetyhubhu yeAluminiyam: Xa utywina umsila, ukugoba kunye nokubamba kwamkela intshukumo ethe tyaba ekhokelwayo ehorizontal (ekuqaleni yayiluhlobo lwe-arc pick-up) intshukumo ngaphandle kokutsala ityhubhu ukuya phezulu.Oku kulungele ngokukodwa imisila ephindwe kathathu.

n.Isixhobo sokukhupha: I-servo ikhupha i-hose yeendlela ezine kwaye inomsebenzi wokulahla.

o.Ukuhanjiswa okuhambelanayo: intshukumo ephakathi kwe-servo, ukuhambisa umkhombe okwahlukileyo, ungqamaniso olulungileyo.

p.I-pressure hopper: ithatha imowudi yokuvula ngokukhawuleza yombhobho wokusabalalisa ukudibanisa kwimpompo yokuzalisa.

q.I-CIP ye-Intanethi: Inokucocwa kwi-intanethi okanye ngaphandle kweintanethi.

Ipharamitha yobugcisa

- Umatshini wokuzalisa iiThubhu Izixhobo eziphambili zeeparamitha zobugcisa

| No | ipharamitha | izimvo | |

| Ukucaciswa kwetyhubhu (mm) | Ububanzi 13 ~ 30, ubude 60 ~ 250 |

| |

| Ukubekwa kwamanqaku kombala (mm) | ±1.0 |

| |

| Ukuzalisa umthamo (ml) | 1.5~200(Dibana ne-5g-50g yeenkcukacha, iinkcukacha ezithile kunye nobukhulu ngokweendidi kunye nobuchwepheshe) |

| |

| Ukuzalisa ukuchaneka (%) | ≤±0.5 |

| |

| Ukutywina imisila | Ukugotywa okuphindwe kabini, okuphindwe kathathu, kunye nokwakheka kwesali kuyafumaneka. |

| |

| Umthamo wemveliso PPm | 250-300 |

| |

| ityhubhu efanelekileyo | Umbhobho weAluminiyam Umbhobho wePlastiki Umbhobho weplastiki weAluminiyam |

| |

| Ukusetyenziswa kwamandla (kW) | ityhubhu yokugcwalisa | 35 |

|

| Irobhothi | 10 |

| |

| Amandla | 380V 50Hz |

| |

| uxinzelelo lomoya | 0.6MPa |

| |

| Ukusetyenziswa komoya (m3/h) | 20~30 |

| |

| Ifom yekhonkco lokudlulisela | (Ithathwe isuka eItali) Udidi lwebhanti ye-Rebar ehambelanayo (i-servo drive) |

| |

| indlela yokuhambisa | I-servo drive epheleleyo |

| |

| ubukhulu (mm) | Ubude 3700 Ububanzi 2000 Ubude 2500 |

| |

| Ubunzima bubonke (kg) | 3500 | ||

I-Smart zhitong inabayili abaninzi abaqeqeshiweyo, abanokuyilaUmatshini wokugcwalisa iityhubhungokweemfuno zabathengi

Nceda uqhagamshelane nathi ngoncedo lwasimahla @whatspp +8615800211936

Iindidi zeemveliso

-

I-imeyile

-

Ifowuni

-

Phezulu

0086 15800211936

0086 15800211936